CREATING PROVEN SOLUTIONS

AlpVision has a proven track record of successfully building working digital solutions, fully integrated with our client’s workflow. See our case studies below for more examples.

CASE STUDIES

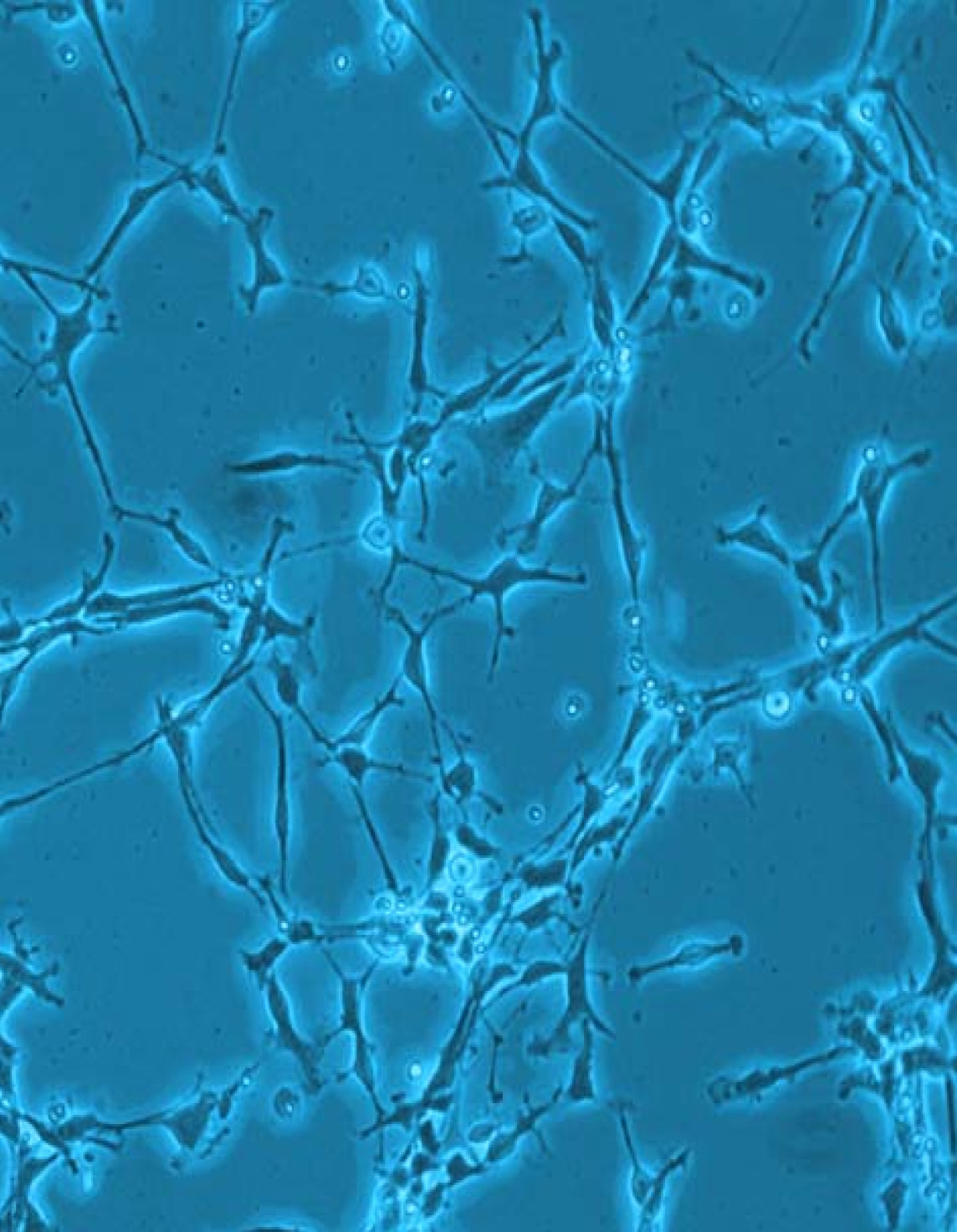

MAMMALIAN CELL CULTURE

PROBLEM

How to monitor mammalian cell culture and digitalize all available data?

In our R&D lab we work on neuronal signaling research. Neuronal cells are very sensitive for culturing conditions. This allowed us to appreciate the importance of stable culture conditions.

SOLUTION

We developed fully automated system for:

- 24/7 remote monitoring: of our cell culture

- Confluence recording and image-based computation

KEY BENEFITS

- Full digital records of our cell culture conditions

- Full remote 24/7 control over what is happening in our lab

CONFLUENCE

PROBLEM

How to accurately measure confluence in cell growth to get accurate results?

Confluence is one of the crucial parameters for monitoring cells growing in monolayer in vitro.

It helps to control the speed of the culture expansion and optimal time for the next passage. In order to ensure the good health of the cells and reproducibility of the experiments the confluence should not be neither too low nor too high. The optimal confluence window and the sensitivity of cells to its deviation, depend on specific cell type.

SOLUTION

We have developed a tool for automatic and accurate assessment of exact confluence based on the phase microscopy image. This tool is successfully used for routine checks of neuronal cell cultures at Final Spark lab.

Our software is based on U-Net architecture, applicable for image segmentation. During the analysis, a UNET map is created, as on the image below. According to this map, computer ‘recognises’ which pixels on the image represent cells. Based on this, a percentage of pixels represented by the cells, as compared to the whole surface, is calculated.

KEY BENEFITS

- much more accurate

- extremely time saving

PREDICTIVE CHEMISTRY

PROBLEM

Experimental optimization of reaction condition for the synthesis of new drug candidates is a costly and time consuming process.

Luckily it can be partly performed in silico, if relevant features deciding about the reaction outcome are properly captured. In this case we worked on retrosynthesis, for which we build a model based on the numerical characterization of four key components: Ligand, Base, Solvent, Reactants.

SOLUTION

Our model predicts reaction yield for different reactants combinations. This allows scientist to limit the number of conditions to be tested experimentally.

KEY BENEFITS

Shortlisting of the reaction conditions for new drug candidates to be tested experimentally helps the scientist to accelerate drug development process.

MEDICAL DEVICES

PROBLEM

How to ensure quality performance of a medical device?

Human cells used for cell-based therapies are very precious material, therefore it is important to avoid their waste due to malfunction of medical devices used for pre-processing of these cells.

SOLUTION

We have developed AI-based system to monitor multiple parameters describing:

- Processed raw material

- Medical device settings

KEY BENEFITS

Our process now delivers stable quality of the performance of the medical device used during preprocessing of cells used for cell-based immunotherapy.

HOW CAN WE HELP YOU?

Give us a few details and we’ll contact you.

Or call to find out more